In industries like construction, stone processing, and precision manufacturing, cutting high-hardness materials can be a daunting task. Conventional blades often fall short due to rapid wear, vibration, and noise issues, resulting in reduced efficiency and increased costs. However, the 400mm brazed diamond saw blade, designed specifically for such demanding applications, offers a compelling solution by enhancing durability, cutting precision, and operator comfort.

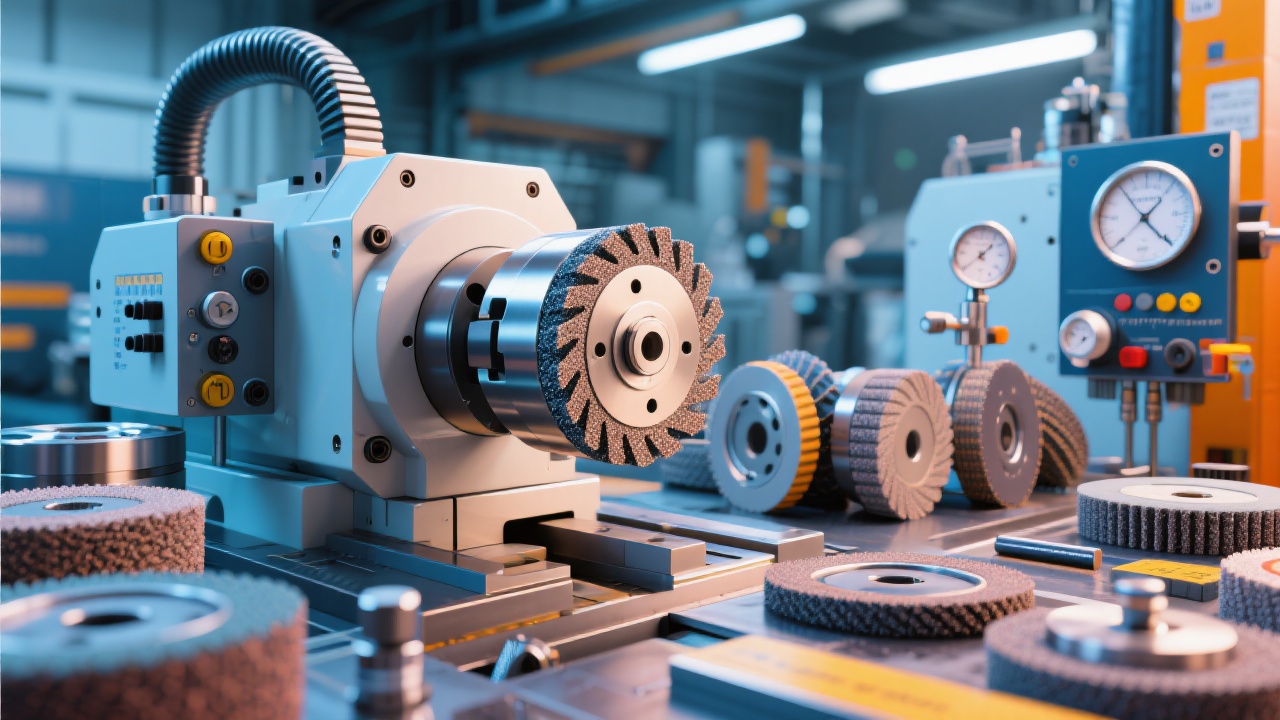

Unlike traditional welding methods, brazing creates a metallurgical bond between the diamond segments and the steel core at elevated temperatures without melting the base metals. This results in a more uniform and robust attachment, significantly enhancing the blade’s wear resistance and cutting stability. According to in-house laboratory tests, blades manufactured with brazing technology exhibit a 25%-30% longer lifespan under continuous cutting of granite and reinforced concrete compared to standard welded blades.

This technical upgrade not only reduces downtime for blade replacement but also consistently maintains cutting accuracy, which is critical for reducing material wastage.

| Feature | Brazed Blade | Traditional Welded Blade |

|---|---|---|

| Segment Bond Strength | High and uniform | Variable, prone to weak points |

| Wear Resistance | Up to 30% better | Standard level |

| Cutting Stability | Consistent with less vibration | Often unstable |

| Typical Noise Level Reduction | ~30% lower (measured) | Higher noise emissions |

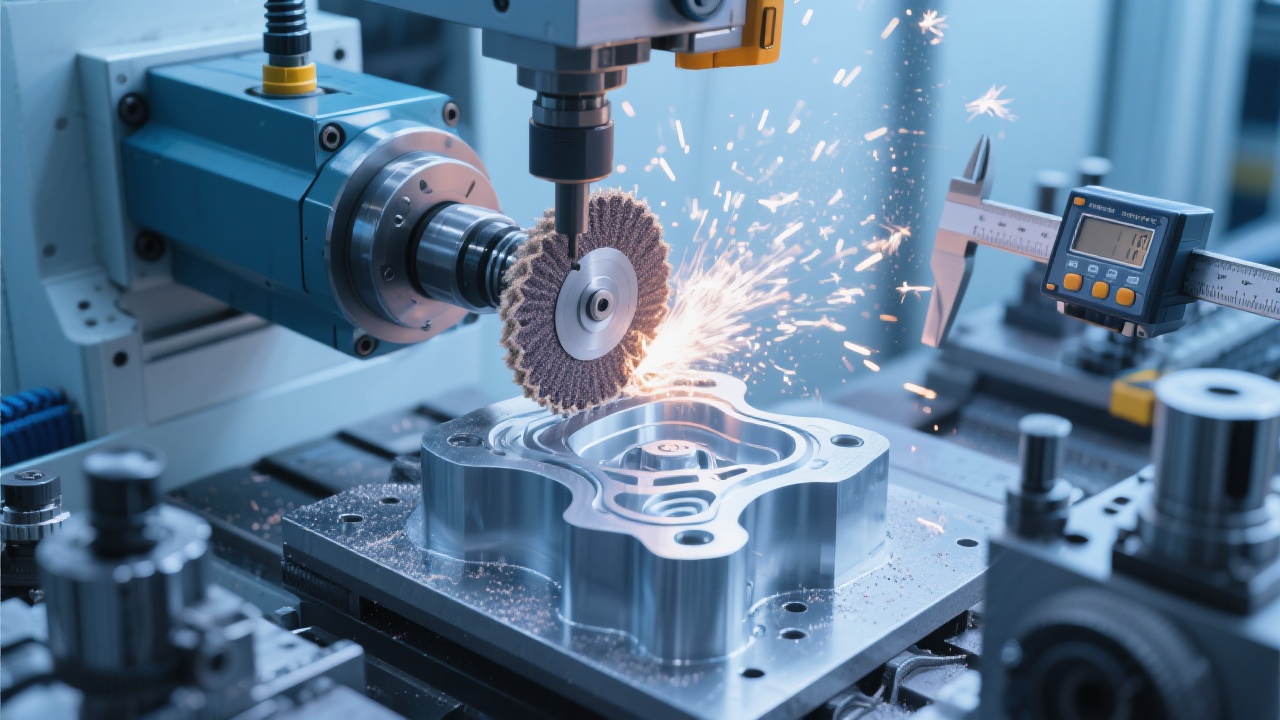

This 400mm blade doesn’t just excel in cutting performance; its optimized tooth and segment geometry dramatically reduce noise and vibration. Laboratory measurements show a noise level reduction of approximately 30% compared to competitive blades under similar workload. The blade’s carefully engineered structure dampens oscillations during operation, contributing to enhanced operator comfort—especially crucial during long cutting sessions.

For professionals, this means less fatigue and improved safety, making every cut feel smoother and more manageable.

One distinctive advantage of the 400H brazed diamond saw blade is its dual-purpose usability. Designed to perform efficiently in both dry and wet cutting environments, it adapts to a wide range of onsite conditions—from indoor construction sites requiring dust control to outdoor stone fabrication where water cooling is feasible. This flexibility translates to significant cost savings and operational efficiency by avoiding the need to switch blades between applications.

Did you know? Using this blade for wet cutting can extend its durability by up to 40%, while dry cutting maximizes portability without sacrificing efficiency.

Consider a recent project in the European stone processing sector, where the client faced challenges with blade wear and noise during granite slab cutting. After switching to the 400H brazed diamond blade, the team reported a 35% increase in cutting speed and a 28% reduction in blade replacement frequency over six months. Notably, onsite operators highlighted the reduction in cutting noise and vibration, improving overall worksite conditions and worker satisfaction.

To sum it up, the 400mm brazed diamond saw blade is not just a tool but a reliable efficiency partner for professionals tackling high-hardness materials. Its engineered design addresses the core pain points of durability, noise, and versatility — truly letting each cut be lighter and more controlled. That said, the final choice should align with your specific site conditions and material profiles.

Have you encountered similar challenges with cutting high-hardness materials? Feel free to share your experiences or specific cutting scenarios below — we'll be glad to provide tailored solutions and case studies from your industry.